NITROGEN CONTROLLERS

BAUER is available to assist through every step of the process of selection and installation. Our experienced staff of GIT experts will assist you with:

-

GIT tool design

-

Part evaluation

-

Process training and development

-

Equipment selection

-

Equipment installation and training

-

GIT mold trial service

-

Gas injectors and nozzles

![]()

Need assistance with selecting the correct solution to meet your specific requirements?

![]()

To see the BAUER Nitrogen Controllers brochure

GAS INJECTION TECHNOLOGY

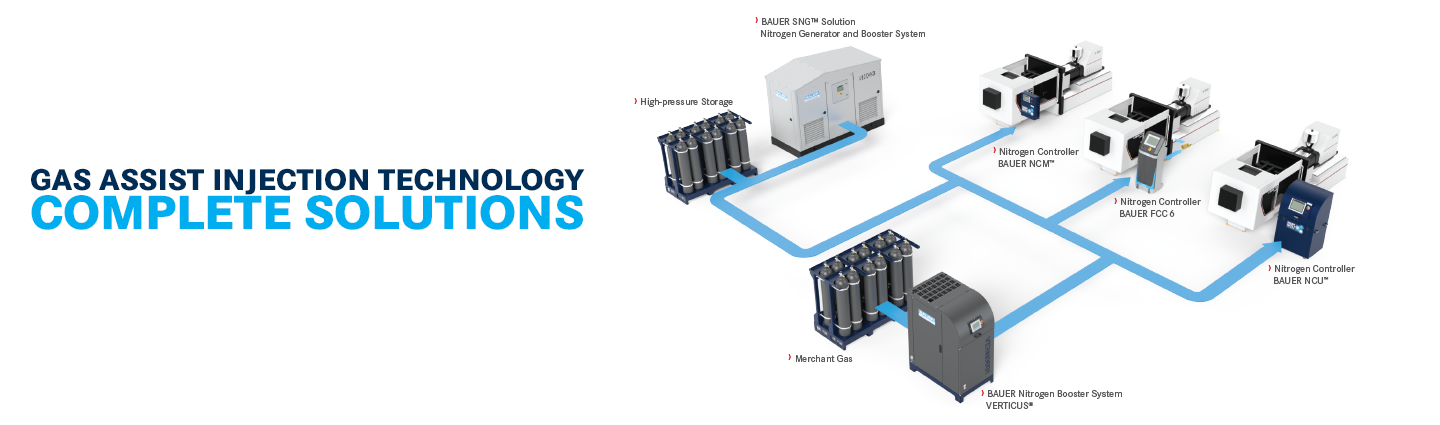

Gas injection technology (GIT) is a low-pressure process where a fluid, usually nitrogen gas, is used to create hollow sections in an injection molded part. The gas flows through the part’s thicker sections or via a network of strategically located gas channels designed into the part to evacuate the molten resin from the channels. This evacuated resin is either used to fill the remainder of the cavity or expelled from the part into a spillover.

The pressurized gas is then used to pack out the part during cooling. The gas pressure, usually ranging from 500 psi to 3500 psi, is much lower than the internal cavity pressure that is required in conventional injection molding. This lower pressure is also distributed more equally throughout the part, thus reducing stress and warp. Higher quality parts and reduced scrap can be realized with GIT.

Another benefit of GIT is the reduction of the clamping force necessary from the injection molding machine. The added gas channels act as flow runners and lower pressure is needed to fill the cavity. Also, the pressure spike from fill to pack is greatly reduced because of the relatively low pressure of the gas. With GIT, parts can be molded in smaller tonnage molding machines greatly reducing manufacturing costs.

Tooling costs can also be reduced with GIT. The elimination of lifters and coring can simplify the mold design and lower maintenance costs.

BENEFITS OF GIT:

- Reduction of part weight

- Reduction of cycle time

- Reduction of clamping force

- Reduced tooling costs

- Higher quality parts

- Reduced manufacturing costs

GAS ASSIST PROCESS CONTROL

Injection molding is a study in precision, a symphony of numerous process parameters working simultaneously to create a single part. If even one of the process parameters is the slightest bit off, the part manufactured can be compromised. This is particularly true with gas-assist injection molding, where the timing of gas injection can make the difference between a quality part or scrap. Given the ever-rising costs of energy and raw materials, you need the assurance that your gas-assist controls can perform consistently and accurately, time and time again.

BAUER understands that reliability and optimal performance are extremely critical for these applications. That’s why we’ve worked for many years to develop the very best gas-assist injection molding solutions in the world. Our control systems are engineered to provide the highest level of pressure control that is repeatable and reliable. When you need control of your gas assist process, BAUER Plastics Technology Group can assist with hands-on consultation and prototyping.

BAUER EXCLUSIVE PROCESS CONTROL FEATURES

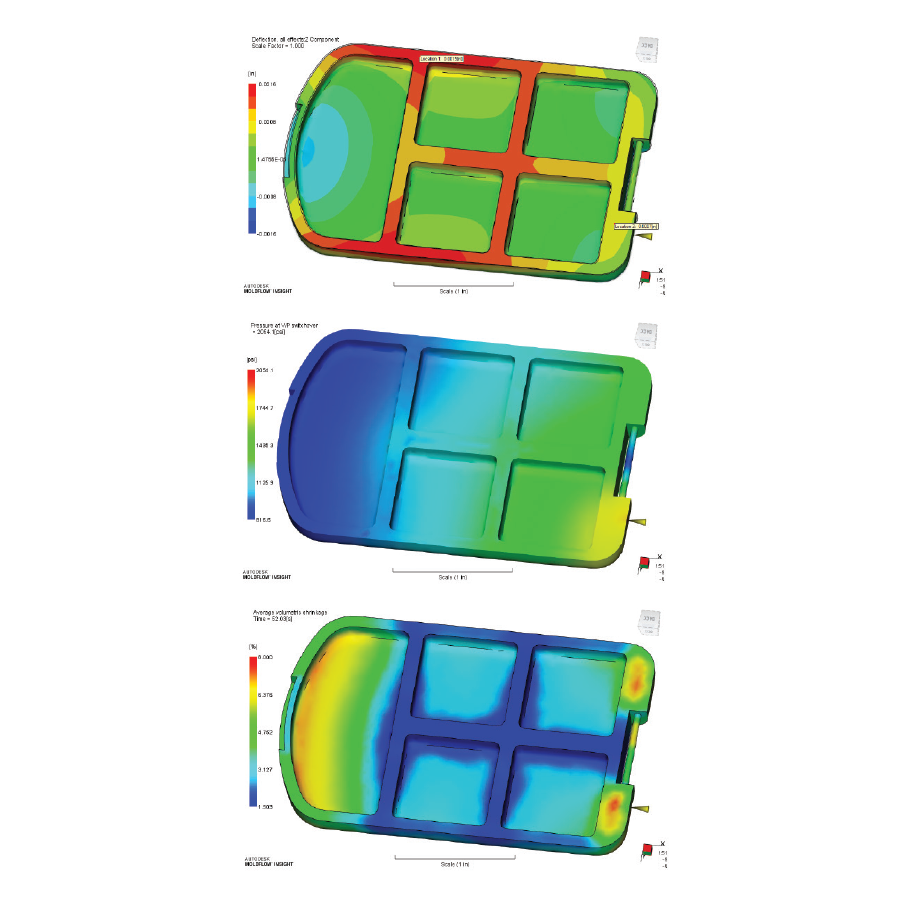

TRUE TRACK RAMPING

BAUER's True Track Ramping technology provides the ability to precisely control the gas injection profile. The processor can program set points to control the rate of gas pressure increase and decrease during each step of the gas injection cycle. With True Track Ramping, you can prevent gas blow through and minimize gas permeation into the thin wall sections of the part.

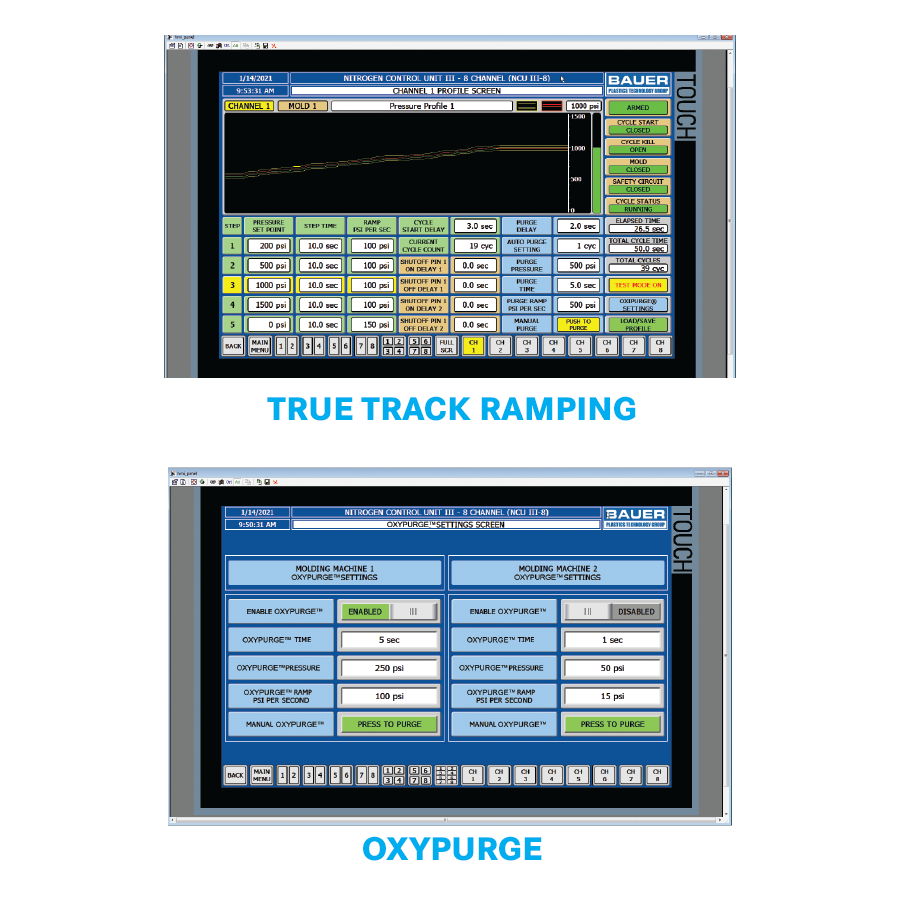

OXYPURGE

BAUER's OXYPURGE technology purges any oxygen from the mold cavity before resin is injected to prevent the burning of the material.