TANKSAFE®

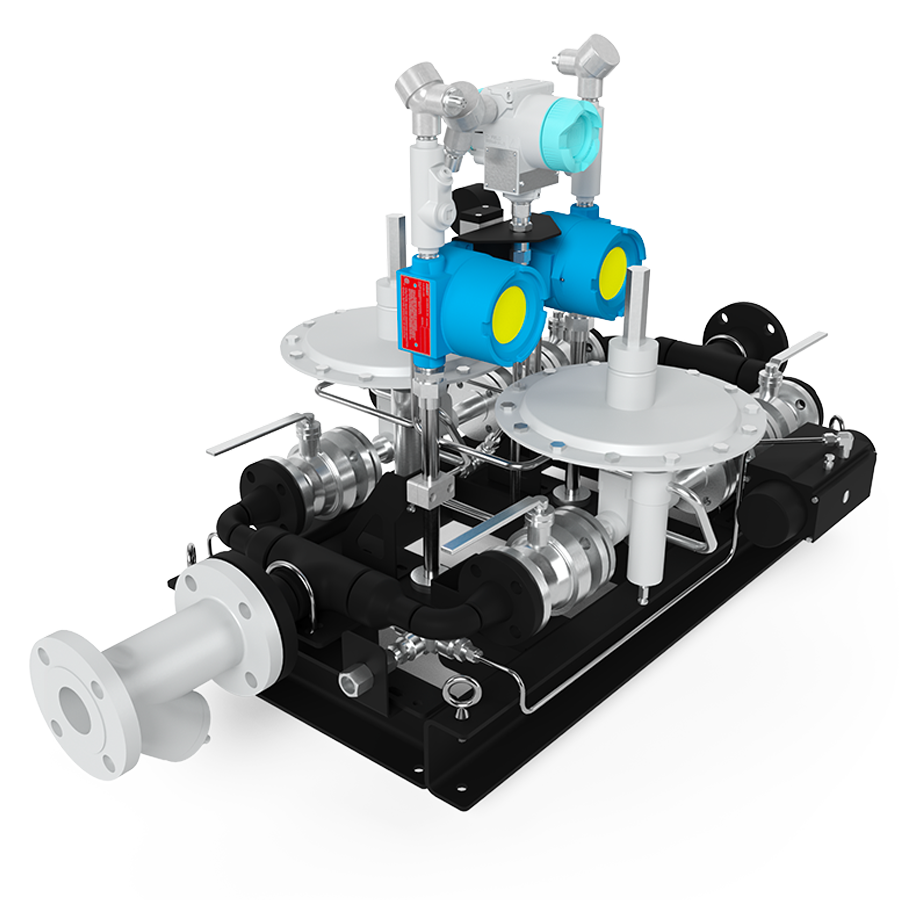

The BAUER TankSafe® tank blanketing system has been specifically designed using BAUER's rugged and time-proven on-demand BAUER NGM® Nitrogen Generation System, combined with BAUER TankSafe® smart tank blanketing control system. Each BAUER TankSafe® system is designed specifically for the nitrogen flow requirements of the customer’s specific tank battery configuration. Required nitrogen flow is based on the dynamic pump-down capacity of the tank battery, as well as thermal contraction factors, and is therefore sized specifically to each site. The goal is to avoid pulling ambient air into the tank(s) inert.

![]()

Need assistance with selecting the correct solution to meet your specific requirements?

![]()

To see the TankSafe® Brochure

THE PROBLEM:

The headspace in liquid storage tanks often contains volatile gases. The presence of these gases can cause an explosion hazard if the mixture between the combustible gas vapor and oxygen in the ambient air is between the Lower Explosive Limit (LEL) and Upper Explosive Limit (UEL). Methane, a common volatile gas found in liquid storage tanks, has a typical LEL concentration of ~5% and a typical UEL concentration of ~15% in ambient air.

These hazardous explosions to a tank battery can lead to:

- Potential millions of dollars in losses due to costs of rebuilding the tank battery lost revenue due to business interruption, and higher insurance deductibles and premiums

- Environmental fines

- Human and environmental safety risks

Inerting liquid storage tanks with nitrogen displace the air in the headspace of the storage tank, thereby reducing the oxygen content in the tank to below hazardous levels.

The BAUER TankSafe® tank blanketing system has been specifically designed using BAUER's rugged and time-proven on-demand NGM™ Nitrogen Generation System, combined with BAUER's TankSafe® smart tank blanketing control system. Each BAUER TankSafe® system is designed specifically for the nitrogen flow requirements of the customer’s specific tank battery configuration. Required nitrogen flow is based on the dynamic pump-down capacity of the tank battery, as well as thermal contraction factors, and is therefore sized specifically to each site. The goal is to avoid pulling ambient air into the tank(s) inert.