![]()

Need assistance with selecting the correct solution to meet your specific requirements?

![]()

To see the entire Helium Systems Catalog

BEST WARRANTY IN THE INDUSTRY

We are so confident in our quality that our helium systems are warranted for two (2) years after the shipment date. This level of support is virtually unmatched in the industry.

24/7 CUSTOMER SUPPORT

All BAUER helium systems are supported by a nationwide network of BAUER factory-trained technicians. We are available 24/7 for technical and spare parts support. We also offer remote monitoring of your system for early problem detection, to ensure the highest level of uptime and reliability for years to come.

Compressing Helium requires special purpose-built compressors.

Helium gas has a density that is 86% less than air. This means that the compressor has to be built to extremely tight tolerances to effectively compress helium gas without excessive blow-by. Furthermore, helium releases large amounts of heat when compressed, which the compressor must be able to absorb and shed. Therefore, for larger helium compressors, BAUER uses water cooling for the compressor for increased cooling efficiency.

Typical helium applications include recovery and compression systems for liquid cooling used in research institutions, particle accelerators, nuclear medicine, aerospace, and military missile applications. Helium recovery and compression is also used in general industrial applications, commercial merchant gas filling plants, heliostat applications, and helium mining.

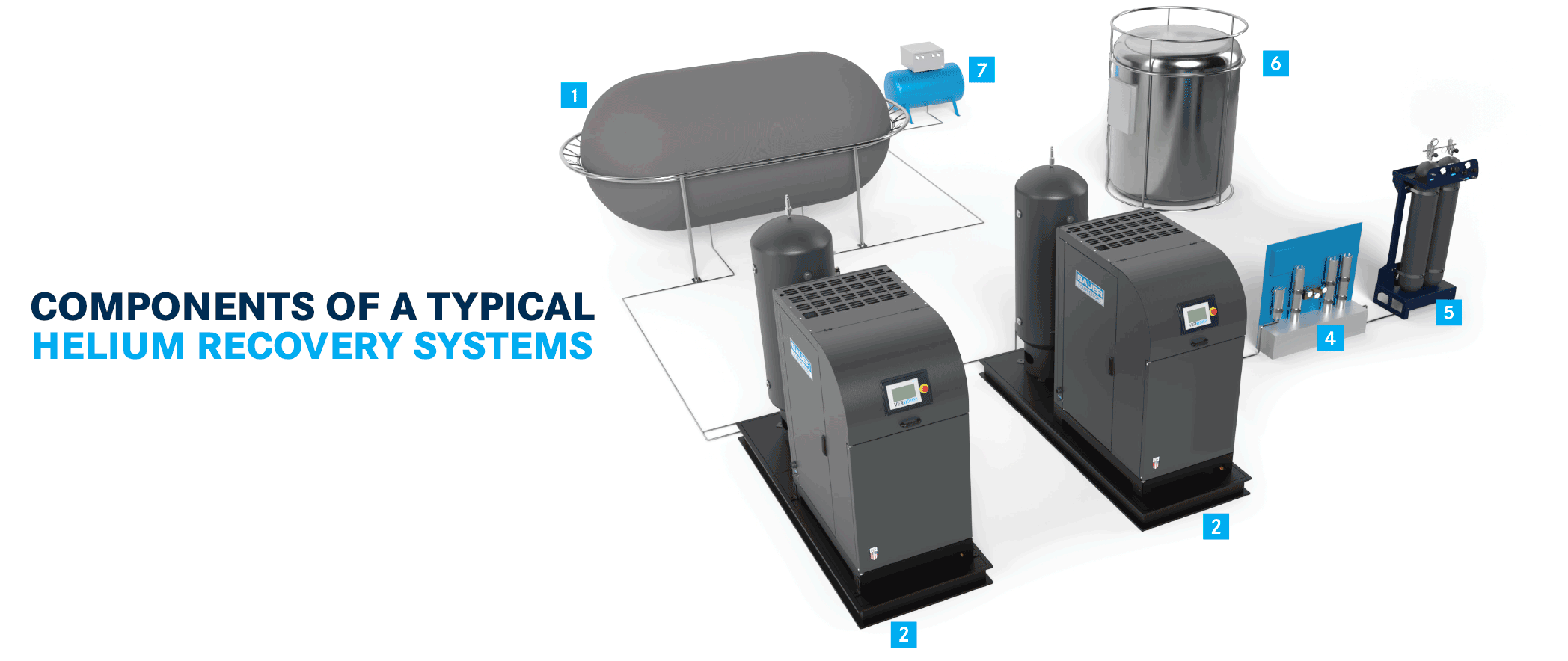

Typical Components of a Helium Recovery System

-

Helium balloon

-

BAUER G-Series helium compressor

-

Dryer/oil removal filtration

-

High-pressure storage system

-

Helium liquefier (generally in universities and scientific institutes)

-

Gas mixer (for feeding helium or gas mixtures in industrial applications)