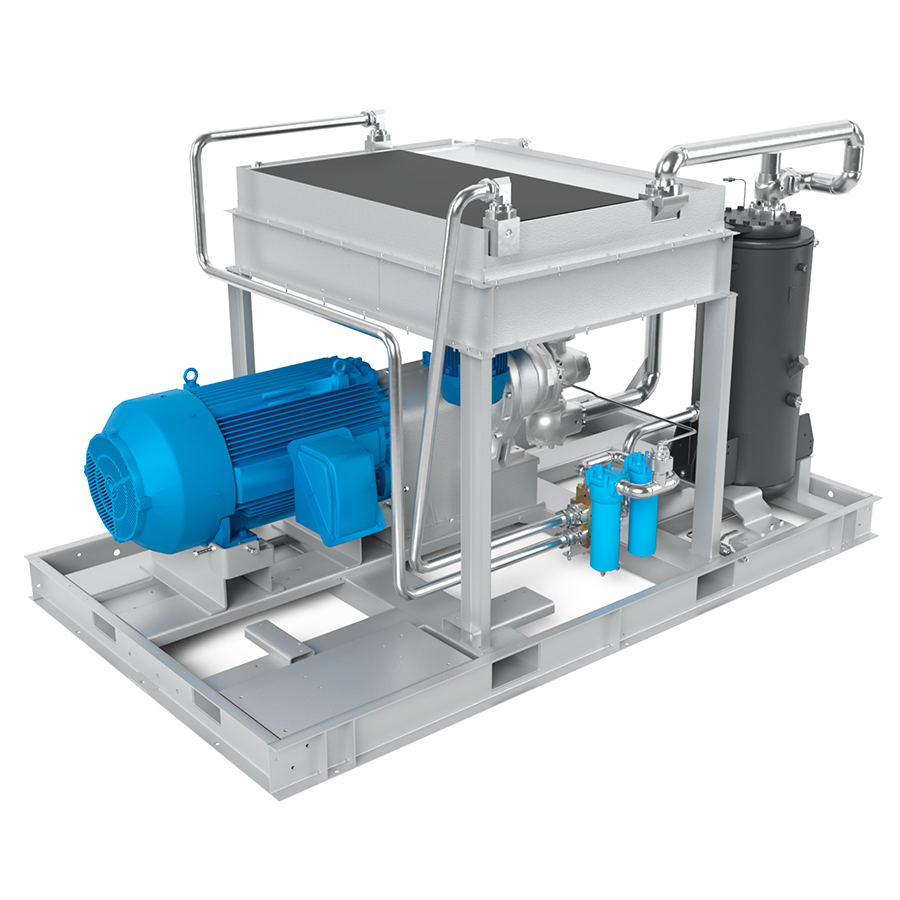

BAUER GRU® HP

The BAUER GRU® Gas Booster rotary screw compressor has been specifically designed for well gas injection into the pipeline grid, for applications which require higher pressures (up to 600 psig) are required. The BAUER GRU® rotary screw booster is also suitable for specific gas turbine power generators which require higher gas inlet injection pressures.

All BAUER GRU® booster units are equipped with variable frequency speed control, which allows the compressor to adjust to the incoming flow of gas. Utilizing a rotary screw compressor for this application is advantageous over reciprocating piston compressors, due to the higher reliability and lower cost of ownership of rotary screw compressors, especially in continuous duty applications.

![]()

Need assistance with selecting the correct solution to meet your specific requirements?

![]()

To see the BAUER GRU® brochure

STANDARD SCOPE OF SUPPLY

- Engineered to operate reliably under continuous duty in harsh conditions

- Designed in accordance with NFPA Class 1, Div 2 standards

- Variable speed drive for precise flow control

- Highly accurate pressure transducer at low inlet pressures

- Stainless steel piping and hardware

- 24-month full warranty, plus lifetime support

- BAUER CONNECT® Remote Telemetry & IoT

TECHNICAL DATA

| FOR GAS BOOSTING APPLICATIONS AT ELEVATED SUCTION PRESSURE AND FINAL PRESSURES UP TO 600 psig (TWO STAGE ROTARY SCREW COMPRESSOR BOOSTER) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| At Stated Max RPM | ||||||||||||

| Model | Motor | Compressor Model | Suction Pressure | Max Final Pressure | Motor RPM | Compressor RPM | SCFM | MMCFD | M3/DAY(1000's) | |||

| HP | kW | PSIG | BAR | PSIG | BAR | |||||||

| GRU 12-350 | 350 | 260 | SP-12 | 100 | 6.9 | 500 | 34.5 | 1790 | 6800 | 1763 | 2.5 | 70.6 |

| GRU 13-350 | 350 | 260 | SP-12 | 100 | 6.9 | 600 | 41.3 | 1790 | 6800 | 1350 | 1.9 | 55 |

| GRU 13-350 | 350 | 260 | SP-12 | 200 | 13.8 | 500 | 34.5 | 1790 | 6800 | 3300 | 4.8 | 134.5 |

| GRU 13-350 | 350 | 260 | SP-12 | 200 | 13.8 | 600 | 41.3 | 1790 | 6800 | 2800 | 4 | 113 |

NOTES: 1) All performance data for compressed gas inlet (suction conditions) is stated at Standard Conditions: Suction Pressure as Indicated, Gas Temperature of 68° F (20° C) and RH of 0%

2) All performance data for compressed gas outlet is stated at ISO 1217 Reference Conditions: Absolute Pressure at 364 ft (111m) elevation = 14.5 psig (1 bar), Gas Temperature of 68° F (20° C) and RH of 0% 3) All performance data are based on a typical well gas composition based on the following Mol percentages: Methane 85.4%, Ethane 8%, Propane 2.9%, Butane 1%, Nitrogen 0.7%, Carbon Dioxide 2%

4) BAUER offers a two-stage rotary screw compressor booster option for higher inlet suction pressures and high flow. All BAUER GRU™ systems are built to Class1, Div2 NFPA standard