![]()

Need assistance with selecting the correct solution to meet your specific requirements?

![]()

To see the BAUER Hydrogen Compressor and Booster Brochure

RELIABLE AND MODULAR

For efficient compression and high reliability thanks to the H2 compatible lubrication system. A quality achieved for fuel cells according to ISO14687.

Complete and modular systems compatible with electrolysis and storage rack for decanting station. The hydrogen compressors are tested and assembled by qualified personnel.

- Outlet pressure: 90 to 350 bar max

- Volume Flow-rate (acc. to ISO1217): 3.1 - 254 SCFM

- Intake pressure: 0.29 - 65 PSIG

- With or without cabinet enclosure

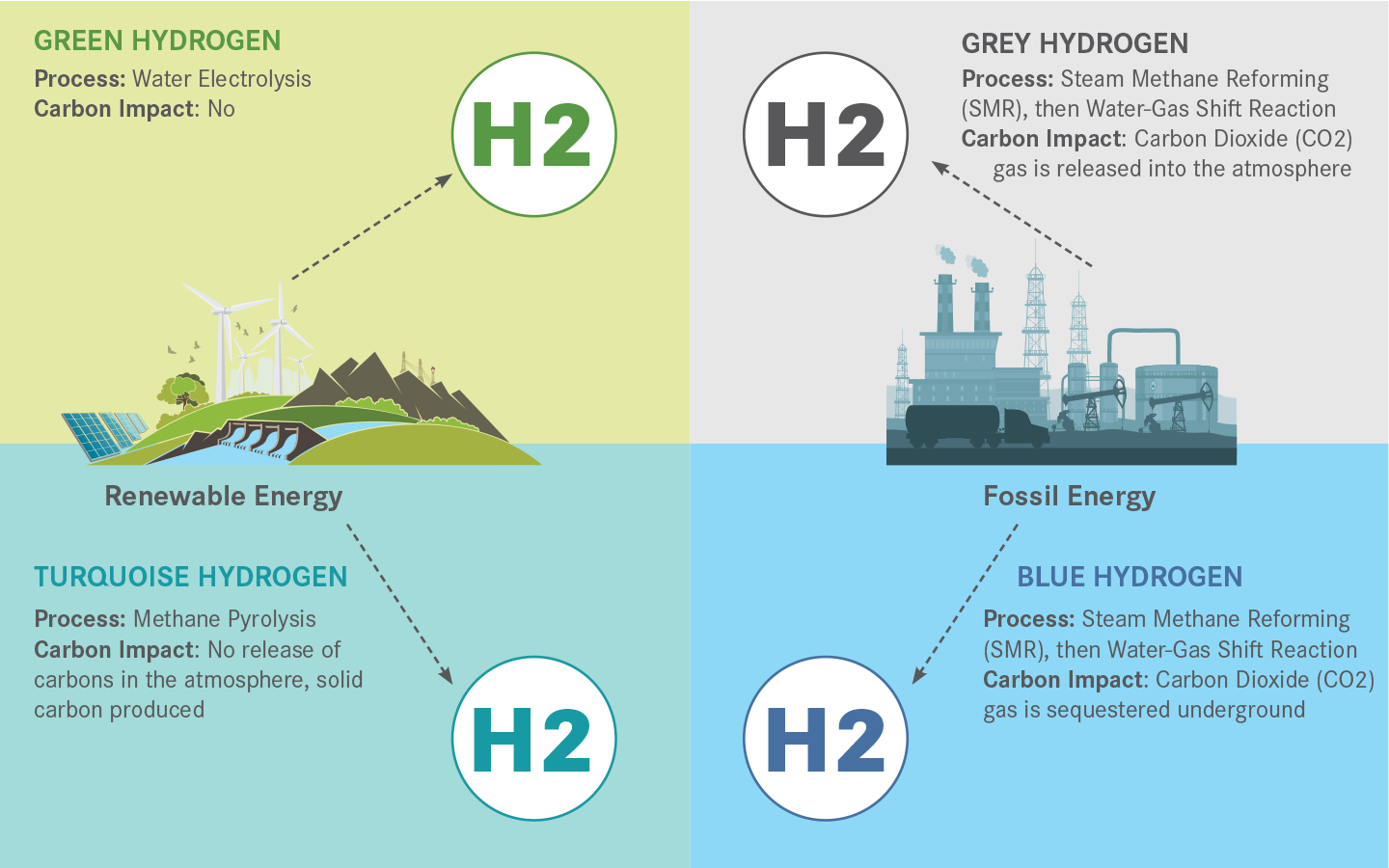

Types of Hydrogen

USES OF HYDROGEN

Hydrogen is used extensively in industry to produce chemicals such as methanol and ammonia. Ammonia (NH3) is often used to create fertilizers and can also be used as a refrigerant (R-717). Hydrogen is essential for producing certain metals and is used to process foods such as hydrogenated oils. It is even used to refine petroleum fuels. But hydrogen is not just relegated to refining conventional fuel sources. For decades, NASA has used it for space travel as a rocket propellant in liquid form, and hydrogen can also be used as a gas fuel or in fuel cells. It can power appliances, vehicles, buildings, and more. 2.2 pounds (1 kilogram) of hydrogen has the same energy as 6.2 pounds (2.8 kilograms) of gasoline. And a benefit of using hydrogen as a fuel is that it does not produce carbon emissions.

TRANSPORT

While it is energy-dense, hydrogen gas is 93% less dense than air. To ensure efficiency in transporting hydrogen, it must be compressed into a high-pressure gas or liquified. It can also be compressed and injected through pipelines, like natural gas. As hydrogen use is anticipated to increase, permanent hydrogen pipelines are proliferating. It can be transported over the road via compressed gaseous tube trailers or cryogenic liquid tanker trucks.

HIGH-PRESSURE SOLUTIONS

Its low density and small molecular size make hydrogen incredibly prone to leaking, and hydrogen molecules react violently with oxygen. The existing molecular bonds break, and the energy held in those bonds is shed explosively as new bonds are formed between oxygen and hydrogen as they bond to create water. As a result, storage containers, tubing, fittings, and other system components designed for use with hydrogen have to be manufactured to the tightest tolerances to ensure the product is contained, and BAUER’s purpose-built hydrogen compressors are made to accommodate these conditions.

HYDROGEN AS A CLEAN TRANSPORTATION FUEL

Hydrogen fuel cell electric vehicles (FCEVs) solve the dilemma presented by the long charge times required by electric vehicles, but still enjoy the same lack of harmful emissions. They can be refueled from pumps like traditional vehicles, but instead of gasoline or diesel, FCEV fueling stations supply highly-compressed hydrogen gas. FCEVs utilize fuel stacks that pass hydrogen through a membrane where it is safely combined with oxygen from the air to produce electricity for powering the vehicle’s motor, and the only emissions generated are water vapor. For larger vehicles, fuel cell motors can be scaled up by adding additional fuel cells for increased power. When it comes to driving range, FCEVs are comparable to traditional engines, owing to the fact that only about 20-30% of the energy created in combustion gets harnessed for propulsion, whereas vehicles using compressed hydrogen gas utilize 60%.