![]()

Need assistance with selecting the correct solution to meet your specific requirements?

![]()

To see the Mobile Pipeline Blowdown and Cross Compression Solutions Brochure

The BAUER GRU® 42 System:

- Capable of blowing down a 36 in, 20 mile long pipeline down from 100 psig to 5 psig in 22 hours and 30 minutes.

BAUER GRU® XL AND XXL SYSTEM OPERATION

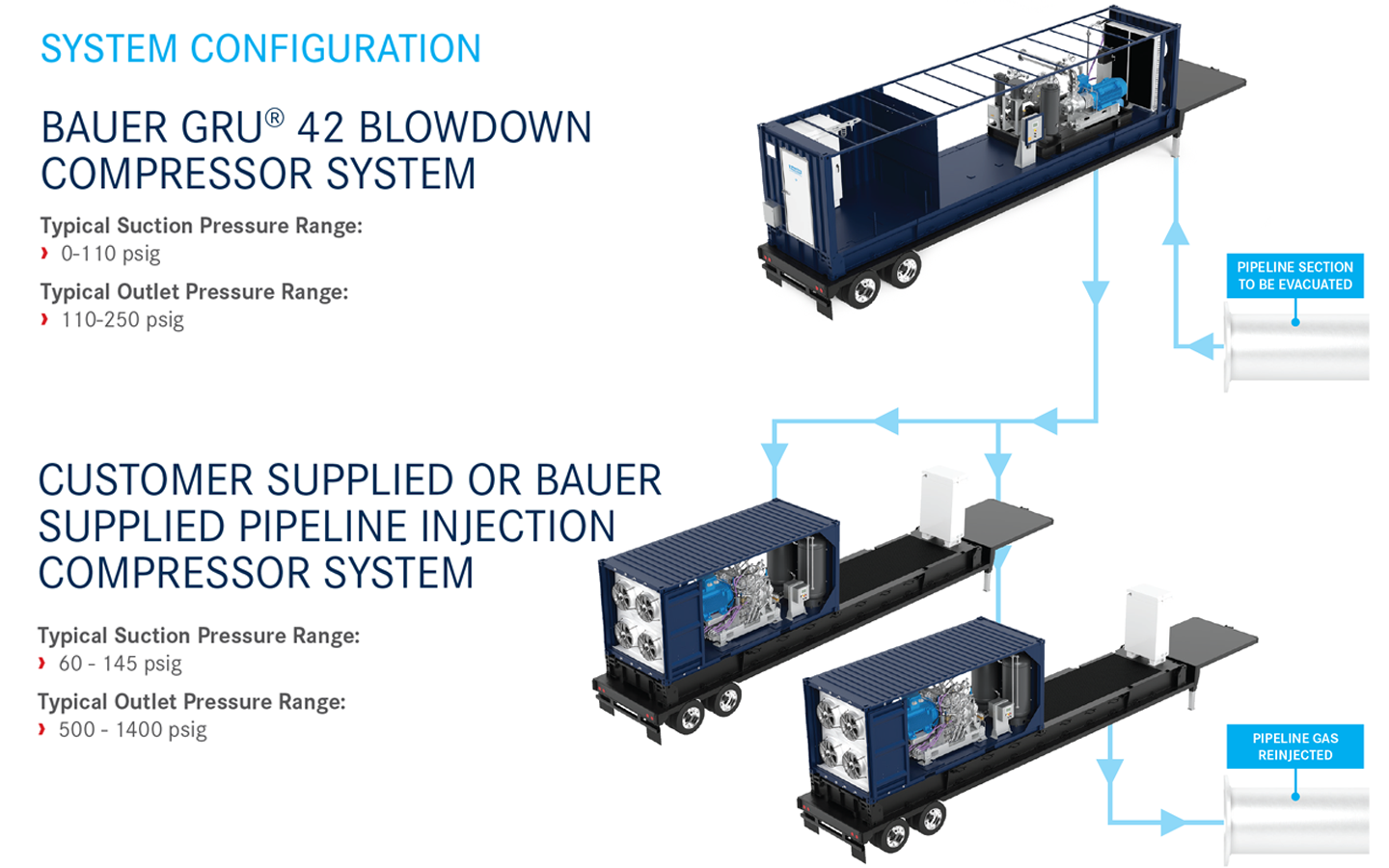

Most reciprocating booster compressors currently used for pipeline blowdown and re-injection are designed to operate efficiently at their optimal flow between a suction pressure range of 100 to 250 psig. As efficient as these systems are, at high inlet pressures (suction pressure into the compressor), their performance declines exponentially as the pipeline residual pressure drops to below 100 psig.

The BAUER GRU® 42 Rotary Screw Blow-down Compressor System is designed to efficiently take pipeline residual pressure from 110 psig down to 5 psig while feeding high-pressure reciprocating booster compressors at their optimal suction pressure to maintain their maximum flow performance. This allows the pipeline blowdown operator to not only take residual pipeline pressure close to zero to meet their customers’ ESG requirements, but to also significantly reduce blow down time in order to satisfy their customers’ tight time-line requirements.

SYSTEM SPECIFICATIONS

Technology:

- The secret behind the BAUER GRU®‘s exceptional performance at low suction pressures is BAUER’s rotary screw gas compressor technology, which allows the compressor to work efficiently at very low inlet (compressor suction) pressures.

- The BAUER GRU® systems are electric drive via VFD so that the speed of the compressor can be precisely modulated based on inlet and outlet conditions.

- In mobile field applications, the electric drive BAUER GRU® blowdown compressor systems can be powered by a standard mobile Natural Gas generator set.

Motor Power:

- BAUER GRU® 42: 1 x 400 HP TEFC motor

Build Standard:

- Hazardous area classification: Class 1, Div II.

- The system is built in a 40-foot custom built ISO container with integrated gas-tight electrical room that houses the VFD.

- The BAUER GRU® 42 compressor system is built for mobility and can be mounted and operated on top of a standard 40-foot trailer chassis.

- All systems are equipped with inlet and outlet gas flanges at skid edge for ease and expediency of making the gas connections to the system.

- For remote field operation, a separate mobile generator set is required to operate the BAUER GRU® systems. All systems are equipped with a handshake relay for generator power.

System Warranty:

- 2-Years parts and labor backed by BAUER’s lifetime support warranty.

BAUER CONNECT® IOT

All BAUER GRU® systems are equipped with BAUER CONNECT® IOT/Remote Telemetry.

This includes the following functionalities:

- Remote operation of the equipment through our Remote HMI feature.

- Remote monitoring of the equipment.

- SCADA systems which present a dynamic visual overview of the system.

- Historical reporting of critical performance parameters customizable per customer wishes.

- Text and e-mail notifications

- Predictive analytics